Industrial Piping Systems

Engineered Piping Systems for Demanding Industrial Environments

Engineered for Efficiency, Reliability, and Long Term Durability

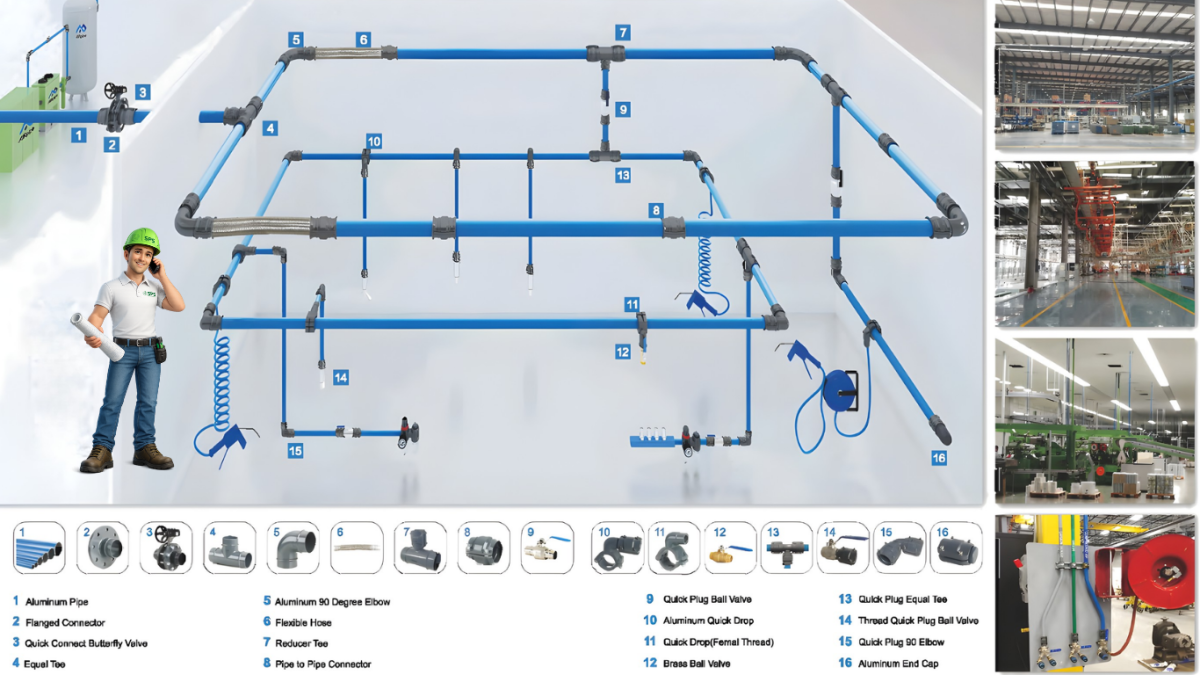

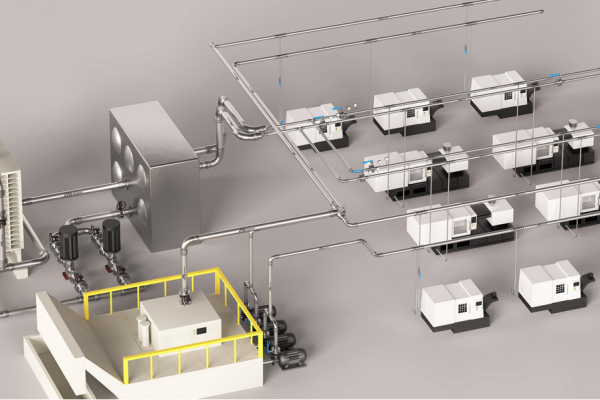

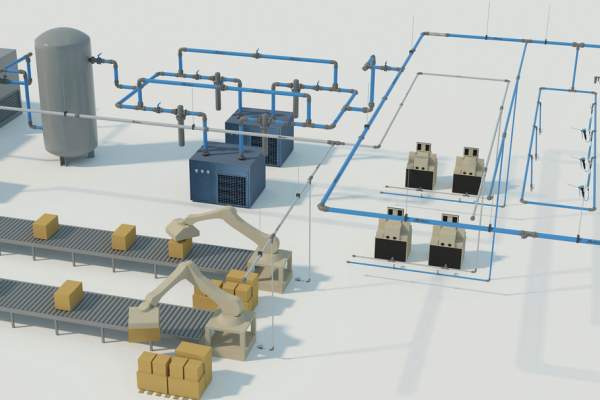

Industrial Piping Systems are designed to deliver clean, efficient, and high performance flow distribution for demanding industrial environments. These systems support compressed air, vacuum applications, and inert gas distribution while maintaining operational reliability and energy efficiency.

Built with durability and flexibility in mind, modern piping infrastructure helps reduce pressure loss, improve airflow consistency, and optimize overall system performance. The modular configuration allows for simplified installation, reduced downtime, and seamless system expansion as operational demands evolve.

Whether your facility requires oil free compressed air, lubricated systems, vacuum distribution, or inert gases such as nitrogen, argon, or helium, these industrial piping solutions provide a scalable and dependable option tailored to complex production requirements.

Characteristics

-

Certified clean air performance compliant with ISO 8573-1 standards

-

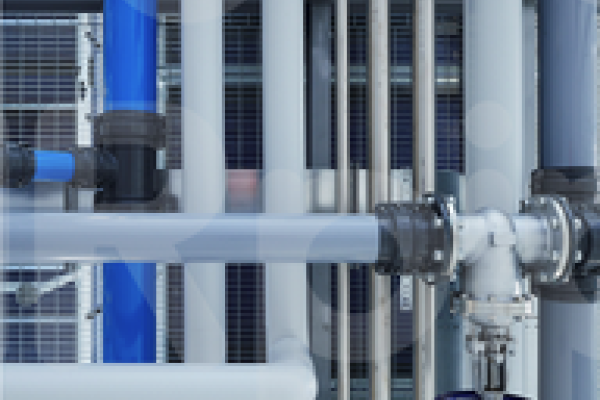

Optimized internal design for maximum flow efficiency and minimal pressure drop

-

Lightweight and modular components for faster, safer installation

-

Durable exterior protection designed for industrial environments

-

Engineered for corrosion resistance and extended service life

-

Suitable for compressed air, oil free or lubricated systems, vacuum, and inert gases including Nitrogen, Argon, and Helium

-

Maximum working pressure up to 16 bar (DN200 up to 13 bar)

-

Vacuum capability down to 1 mbar absolute pressure

-

Operating temperature range from -4°F to +176°F (-20°C to +80°C)

Industrial Piping Systems are built to enhance performance, improve energy efficiency, and provide long term operational reliability across a wide range of industrial applications.